| The rebuilding of Hodgson Mill is completed! In an article in the Ozark County Times, new owners Hank and Jean Macler invited anyone interested to come and watch the work. On Saturday, March 10, 2001, a crowd gathered to watch the workers set the last beam in place. |

|

More information: More information:

Hodgson Spring: some facts and figures

Hodgson Mill: some history

|

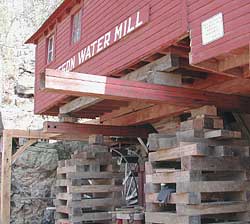

| The mill owners found that years of weather and neglect had weakened the century-old timbers under the mill. Now local craftsmen are making it possible for the mill to stand for another hundred years. |

| Members of the Amish community in Seymour joined with workers from Howard House Moving Company in Dora for the work of removing old timbers and replacing them with new ones. |  |

| The workmen came on Saturday to set the last beam in place. They had left this last beam unfinished so people could see how the timbers were put together. |

| Weeks ago, special steel beams, made of half-inch steel pipe reinforced with angle iron, were inserted under the mill. These were used to lift the mill off the old supports. |  |

Workers from Howard House Moving Company used heavy jacks to raise and support the structure.

The beams, resting on timber cradles, have been supporting the mill since then. |

| The old supports had to be removed so the Neises Concrete Company could pour concrete footings for new ones. Later, the footings will get a natural stone facing. |

| Sometimes they had to adjust the footing. Here they've poured an additional layer to bring it to the right height. |  |

| Amish carpenters shaped the timbers using hand tools. This massive white oak post will rest on the concrete footing when the mill is lowered. |

| The horizontal beam to the left is one of two long horizontal beams running the length of the mill from front to back. Each one is made of Douglas fir. |  |

| They have notched the timbers to create holes, called mortises. You can see a mortise in the timber on the left. The tongue, or tenon, on the short timber on top, will fit into a mortise. |

| Wooden pins are then hammered through holes drilled through both sides of the joint to hold the two pieces in place. This creates a very strong and long-lasting bond. Most buildings in the 19th century and before were built this way. Nails had to be made by hand by blacksmiths. They were expensive and hard to find. |

| Here you can see two pins, one marked with a Roman numeral. The woodworkers carved this number so they could match it with the correct piece. The whole thing is like a huge wooden puzzle! |

| A pile of beams with finished mortises and tenons. The carpenters cut these to size in their workshop. They used the architect's drawings, and they also took measurements at the mill, to make everything fit perfectly. |  |

| The last beam goes into place. |

| The backhoe lifted the beam up. |

The Amish workmen had cut it to fit exactly into place. |  |

| Sliding the beam's mortise in over the post's tenon. |

| They had to fit the tenons of each brace into the mortises of the beam at the same time it was being fitted into place. It was indeed a puzzle! |  |

| All the parts finally fit together. The pins went in with ease. The crowd gave a big cheer! |

The finished post and beam structure in place. |  |